Story

Our beginnings

The founding partners embarked on a new project and in 2013 acquired their second company, the defunct “LAED, industrias plásticas SL”.

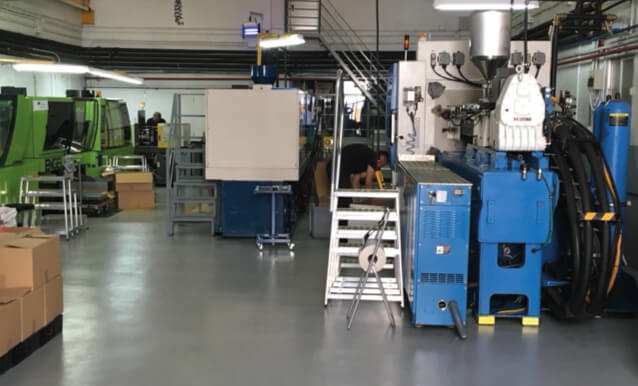

Under the name of DINTEC S.L. (Design, injection and industrial technology S.L.) we started a process of modernisation by replacing the existing machines with others with a more sophisticated configuration.

At the same time, we were adapting our facilities.

Little by little, we were making a name for ourselves in the sector, both in our area and in the rest of the peninsula.

Year 2015

new machinery

We already had a renovated site and acquired new machinery:

- HUSKY 225 tn.

- Ultrasonic sealing machine S-2000.

Year 2015

Year 2016

we expanded services

We partnered with the AIJU Technological Institute and incorporated two injection moulding machines:

- Fanuc 15tn.

- Engel 120 tn ecodrive.

Year 2016

Year 2017

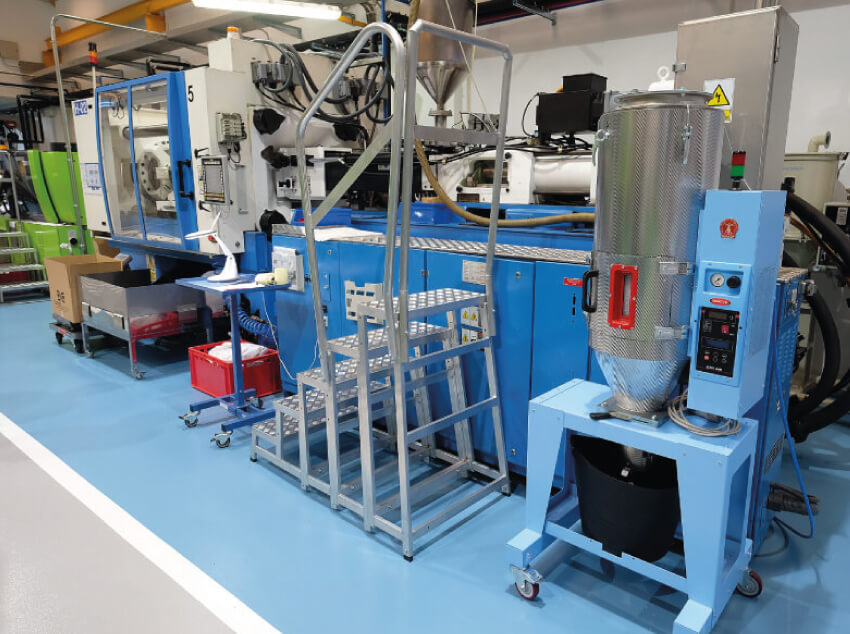

Upgrade of Dintec’s facilities

- We renovated the cooling system of the facilities. We also renovated the electrical installations and rebuilt the pavement.

Year 2017

Year 2018

New acquisitions

- Engel 140 tn injection moulding machine.

- Engel 180 tn injection moulding machine, with capacity for 600gr in PP.

Year 2018

Year 2019

Looking for our seal of quality

At Dintec we incorporated ISO 9001 certification with BUREAU VERITAS and implemented the digitalisation project for SMEs in the Valencian Community.

Year 2019

Year 2020

Following our path of innovation

We try to keep up to date with all the trends in the plastic injection moulding sector, so we joined Industry 4.0 and we go for high-end peripheral devices:

- Husky temperature controllers.

- Dehumidifiers.

- Dosing units.

- Feeders.

- Temperature controllers.

Year 2020

Year 2021

Commitment to the environment

We are once again expanding Dintec’s machine park with two new additions:

- Toyo 50 tn, fully electric.

- Heat sealing machine.

Year 2021